Category: How To

A floor jack for car is one of the most basic of tools in a garage. It does not matter whether you are a professional or not. Most of the modifications needed ...

READ MORE +Difference between Repair VS Replace If you have a car, there are a number of things that you should have in your inventory and a floor jack is one of them. ...

READ MORE +Vehicles are part and parcel of our daily lives and they are necessary for the day to day activities. However, there are moments when you will have to carry ...

READ MORE +When you buy a new floor jack, it should be able to serve your needs for a very long time. However, the lifespan of the floor jack, solely depends on the ...

READ MORE +A floor jack is quite essential when it comes to lifting vehicles. Without a proper jack; it is almost impossible to be able to lift a vehicle off the ground. ...

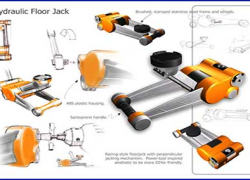

READ MORE +What’s the Best FLOOR JACK for Your Garage? Having the right tools in your workshop is the key to ensuring that you are able to perform tasks in a relatively ...

READ MORE +