Category: How To

Maintain a floor jack mostly depends on how and when it is used. Many people use the jack to change the tire now and then. On the contrary, as a ...

READ MORE +Safety and comfort are paramount wherever you are and that includes even in your car. You want to be able to access all the basic items for your well-being at ...

READ MORE +An oil change is one of the most important maintenance jobs if you want to increase the longevity of your car. That being said, it's also one of the easiest ...

READ MORE +Car ramps are mechanical devices that are used for lifting up your car so that you can have an opportunity to carry out various repair works underneath the ...

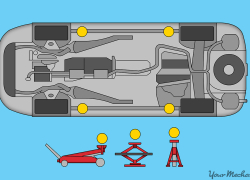

READ MORE +Are you searching for an informative article on how to jack up a car from the front? When working under your vehicle, one thing you should bear in mind is ...

READ MORE +Do you want to know how to use a scissor jack? A scissor jack also called the basic jack is usually in your car's trunk. You may need to use it one day, ...

READ MORE +When's the last time you inspected your floor jack? Do you know if all its parts are working properly? Just like any other piece of equipment, it's ...

READ MORE +A hydraulic jack is a device used in force lifting heavy loads such as a car. The Jack uses screw thread or hydraulic cylinder in lifting the loads. Steps on ...

READ MORE +Almost every driver runs the risk of getting a flat tire, and need to jack up their vehicle. It is, therefore, pertinent to know how to do it right. Jacks ...

READ MORE +How To Install Subwoofer In a Car Step By Step Guidelines When we are all concern about our car music system, it is important to understand first, what type ...

READ MORE +![How to Bleed a Floor Jack [The easiest way]](https://bestfloorjackreview.com/wp-content/uploads/thumbs_dir/Bleed-a-Floor-Jack-22jfxsnq1t0og35mtgcl3f5w5dnt3q556sukgkxs93es.jpg)